Rugged Control Systems for Construction Machinery

SonnePower develops robust electronic control systems for construction machines such as excavators, cranes, and concrete mixers. Our IP67-rated, CAN-based solutions ensure reliable operation, smart diagnostics, and seamless integration in harsh construction environments.

Industry Challenges and Opportunities

The construction industry is rapidly evolving with automation, smart sites, and new energy machinery creating opportunities. Yet harsh conditions, rising labor costs, and integration demands remain challenges. Rugged, intelligent control solutions are key to success.

Sonnepower Construction Control Solutions

To address key challenges in construction machinery, SonnePower offers intelligent control solutions—controllers, displays, I/O modules, motor drives, and operator panels—designed for reliability and efficiency on tough job sites.

Labor costs high, low efficiency

SonnePower controllers enable automation logic to reduce manual intervention and boost productivity.

✅ Programmable controller + CoDeSys platform

🎯 Fewer operators, higher efficiency

Harsh working environments

SonnePower controllers, I/O modules, and displays are IP67-rated, resistant to temperature extremes, dust, and vibration.

✅ Rugged industrial-grade design

🎯 Reduced failure rate, longer lifespan

Difficult equipment management

With CAN bus protocol, SonnePower systems enable remote monitoring and diagnostics for smart maintenance.

✅ CANopen / J1939 support

🎯 Fast troubleshooting, remote service

High safety risks

SonnePower displays and control systems integrate with cameras and sensors to deliver real-time data and alerts.

✅ HMI + safety monitoring logic

🎯 Reduced accident risks

Low equipment intelligence

Controllers and modules support flexible I/O configuration and complex logic, enabling rapid smart upgrades.

✅ Modular architecture

🎯 Fast smart retrofit

High fuel consumption, low efficiency

Smart control and data feedback optimize power output to cut energy use.

✅ Precise output control + condition sensing

🎯 Energy savings, eco-compliance

-

Supports CoDeSys 3.5 and IEC 61131-3 programming standards

-

Operating temperature range: -40°C to +85°C, suitable for harsh environments

-

Built-in CAN Bus communication for seamless integration

-

IP67-rated protection ensures dust and water resistance

-

Compact design enables easy installation on various agricultural vehicles.

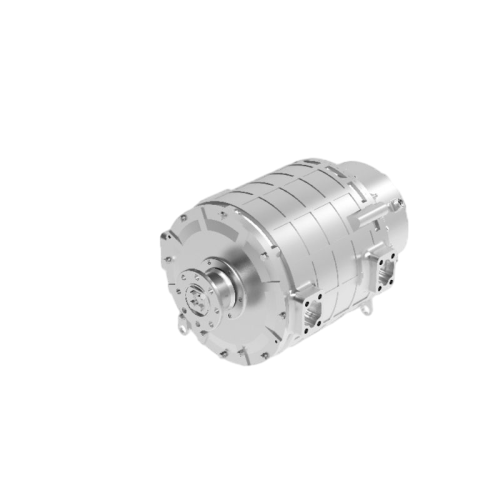

- Integrated motor and controller

-

Liquid-cooled for stable performance

-

CAN communication with diagnostics

-

IP67-rated for harsh environments

-

Vector control with ±3% accuracy

-

ISO 26262 safety compliant

-

Maintenance-free and easy to install

- Available in 4.3″, 7″, 10.1″, and 12.1″ screen sizes

- Programmed via CODESYS 3.5, supporting CANopen, J1939, and custom protocols

- Some models support fast boot within 5 seconds

- Customizations include UI layout, company logo, and startup animation

-

8, 12, 16, 17, or 20 key options

-

Plastic housing with silicone rubber overlay

-

Replaceable key symbols (pre-designed or custom)

-

Supports CANopen, J1939, and custom protocols

-

1x DOH digital output

-

White backlight with adjustable brightness

-

RGB single-color or tri-color LED indicators

-

IP65/IP67 protection with cable connected

-

8, 9, 11, 26, or 32 I/O channels available

-

IP67-rated for outdoor and harsh environments

-

Reverse power and ground fault protection on all ports

-

Short-circuit and overheat protection on all outputs

-

Open-circuit detection for all output channels

-

Compact size for easy installation and wiring