Smart Control Solutions for the Sanitation Industry

Empower sanitation vehicles with intelligent controllers, rugged displays, I/O modules, and efficient motor systems tailored for demanding environments.

Industry Challenges and Opportunities

With rising environmental standards and urban expansion, the sanitation industry faces growing pressure to operate more efficiently, reduce emissions, and lower labor costs. This transformation drives demand for intelligent, connected, and robust control systems in sanitation vehicles.

Stricter regulations

Vehicles must reduce emissions and noise

Rising labor costs

Demand for more automation and precision

Diverse conditions

Systems must endure dust, vibration, and harsh weather

Digital Demand

Integration with fleet management and data systems

Typical Application Scenarios

Compactor Garbage Truck

📌 Applicable Products:

👉 Controller

👉 I/O Module

👉 Display

Controllers enable automation of compression, lifting, and unloading functions. Displays help operators monitor system status in real-time.

Swing Arm Garbage Truck

📌 Applicable Products:

👉 Controller

👉 I/O Module

Ideal for community waste collection.

Controllers manage lifting mechanisms and ensure reliable, safe operation.

Street Sweeper

📌 Applicable Products:

👉 Controller

👉 Display

👉 Motor System

Controls brushes, motors, and water pumps for automated sweeping.Display provides real-time feedback and fault alerts.

Water Sprinkler / Dust Suppression Truck

📌 Applicable Products:

👉 Controller

👉 I/O Module

👉 Motor System

Used for urban dust control and road spraying.

Supports timed, manual, and remote spray control with consistent water pressure.

High-Pressure Cleaning Vehicle

📌 Applicable Products:

👉 Controller

👉 I/O Module

👉 Motor System

Designed for street and facility cleaning.

Controls manage pump start/stop, pressure levels, and multi-mode operation.

Sonnepower Sanitation Control Solutions

Sonnepower provides intelligent control solutions for sanitation vehicles, including controllers, displays, I/O modules, motor drives, and operation panels.

-

Supports CoDeSys 3.5 and IEC 61131-3 programming standards

-

Operating temperature range: -40°C to +85°C, suitable for harsh environments

-

Built-in CAN Bus communication for seamless integration

-

IP67-rated protection ensures dust and water resistance

-

Compact design enables easy installation on various agricultural vehicles.

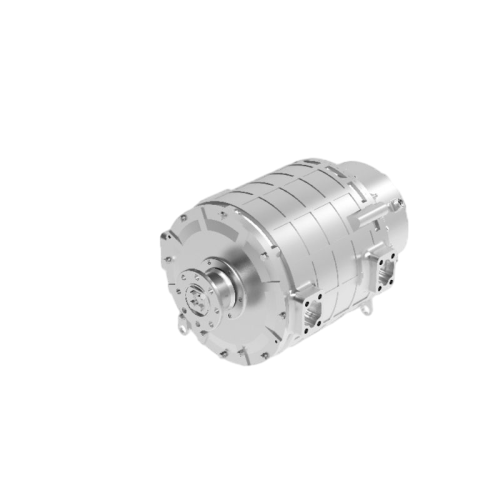

- Integrated motor and controller

Liquid-cooled for stable performance

CAN communication with diagnostics

IP67-rated for harsh environments

Vector control with ±3% accuracy

ISO 26262 safety compliant

Maintenance-free and easy to install

- Available in 4.3″, 7″, 10.1″, and 12.1″ screen sizes

- Programmed via CODESYS 3.5, supporting CANopen, J1939, and custom protocols

- Some models support fast boot within 5 seconds

- Customizations include UI layout, company logo, and startup animation

-

8, 12, 16, 17, or 20 key options

-

Plastic housing with silicone rubber overlay

-

Replaceable key symbols (pre-designed or custom)

-

Supports CANopen, J1939, and custom protocols

-

1x DOH digital output

-

White backlight with adjustable brightness

-

RGB single-color or tri-color LED indicators

-

IP65/IP67 protection with cable connected

-

8, 9, 11, 26, or 32 I/O channels available

-

IP67-rated for outdoor and harsh environments

-

Reverse power and ground fault protection on all ports

-

Short-circuit and overheat protection on all outputs

-

Open-circuit detection for all output channels

-

Compact size for easy installation and wiring