CAN Bus IP65 Codesys Outdoor Mobile Machinery Displays

SonnePower displays are built for harsh mobile machinery with IP65 dust and water resistance and strong vibration protection. They support CANopen, J1939, and custom CAN protocols for seamless integration.

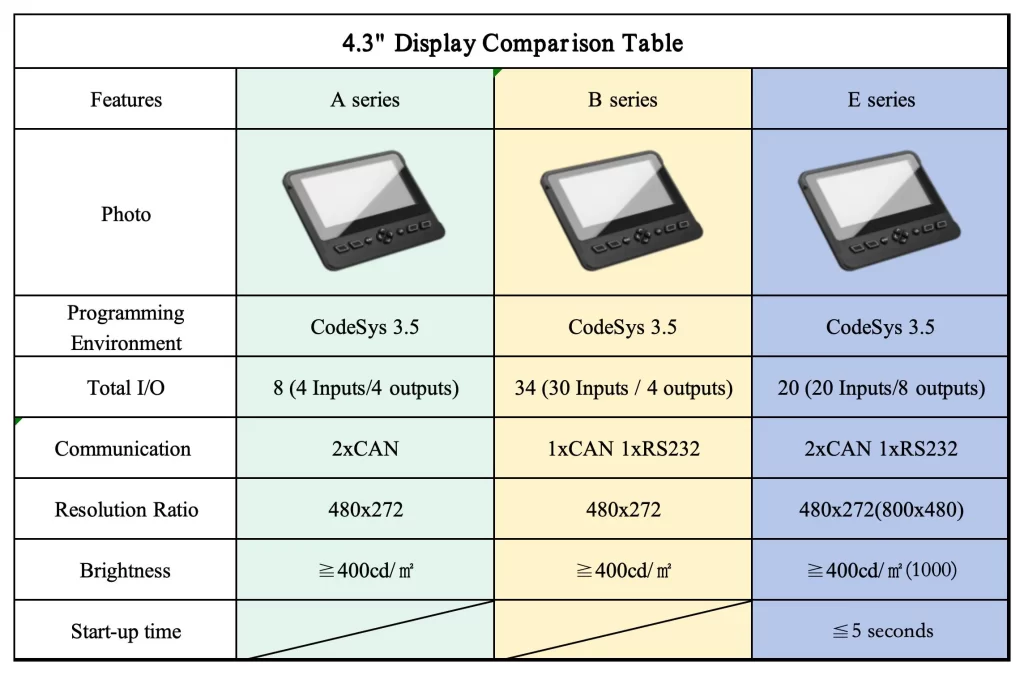

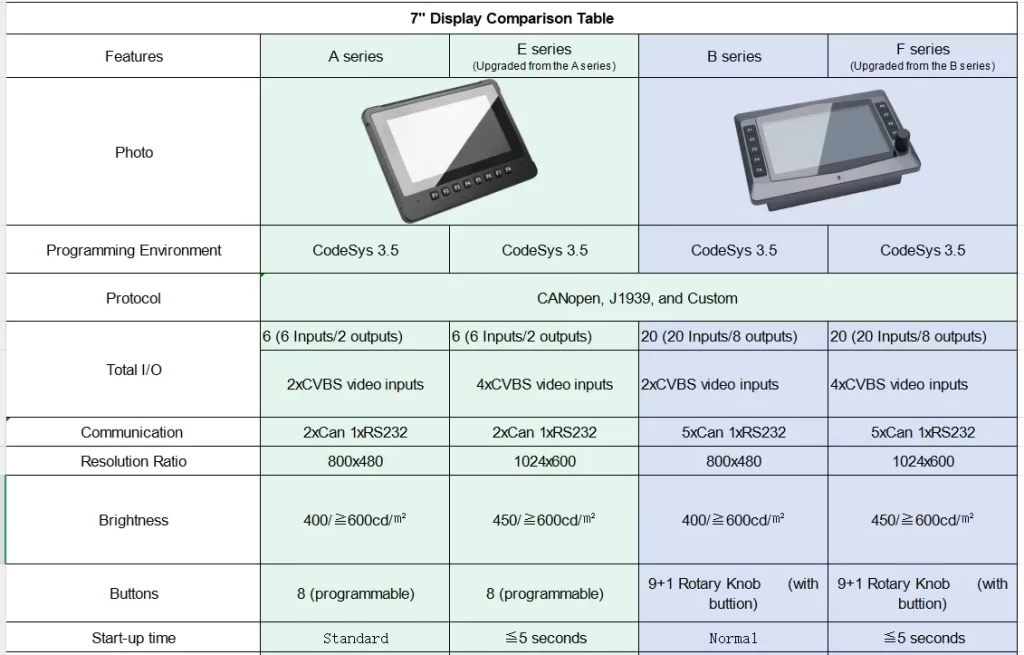

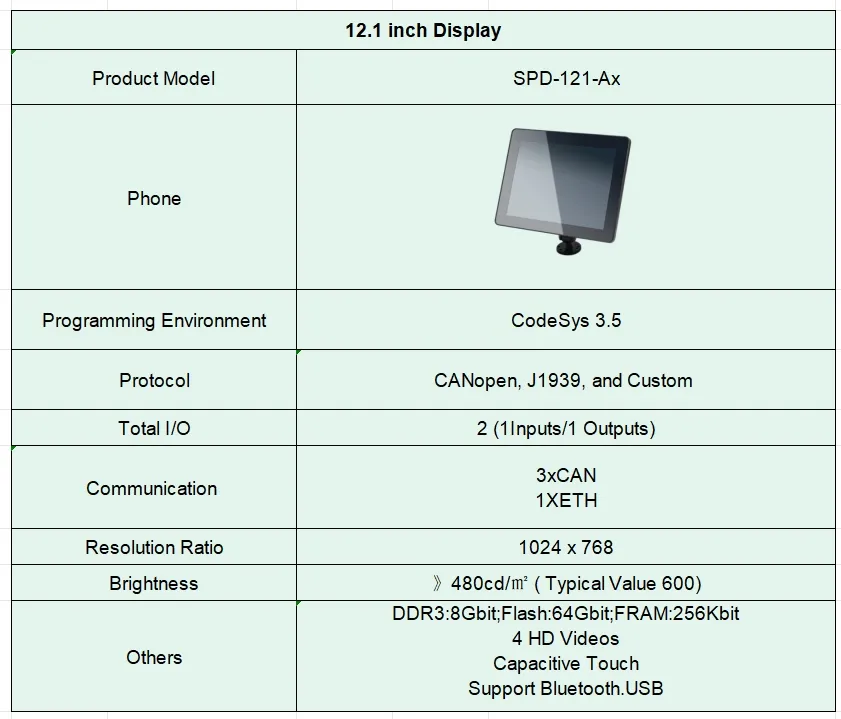

Equipped with CODESYS 3.5 programming environment and versatile I/O modules, they provide flexible control solutions.

High-brightness, sunlight-readable screens feature multi-touch. Interfaces include RS232, RS485, and Ethernet, with wide 8-32VDC input for power compatibility. Comprehensive after-sales support and custom solutions enhance efficiency and reliability.

Applications of Rugged Controller in Mobile Machinery

1. Aerial Work Vehicle 🏗️

Real-time display of lift height, angle, and safety status.

Visual alarms for tilt and overload warnings.

Intuitive HMI for operator status feedback and diagnostics via CAN bus.

2. Drilling Rig ⛏️

Displays drilling depth, motor speed, and pressure data in real time.

Alerts for abnormal vibrations or drill resistance.

Customizable UI via CoDeSys for tailored control visualization.

3. Excavator 🚜

Visual feedback for boom, arm, and bucket positions.

Monitors load, hydraulic pressure, and engine health.

Touchscreen interface simplifies control and status monitoring.

4. Loader 🚛

Displays lift height, tilt angle, and bucket load.

Alarms for oil temperature, hydraulic anomalies, or speed thresholds.

Multi-protocol communication enables seamless HMI integration.

5. Crane 🏗️

Real-time monitoring of boom angle, extension, and load weight.

Displays limit status, stability indicators, and alerts.

Supports remote display mirroring for off-vehicle monitoring.

🛻 Mining Trucks

Real-time visualization of propulsion, braking, suspension, and dump bed status.

Supports remote monitoring and diagnostics for enhanced safety and efficiency.

High-brightness display ensures readability in dusty and high-glare environments.

🚛 Articulated Dump Trucks

Displays steering angle, articulation status, and tilt warnings.

Multi-touch interface improves operator intuitiveness.

Seamless integration via CANopen / J1939 protocols.

⛏️ Underground Loaders

Provides critical operation feedback in low-visibility, confined spaces.

Integrated alerts and safety redundancy features enhance operator protection.

High IP-rated housing withstands shock, water, and dust in underground conditions.

🚚 Heavy Haul Trucks

Monitors engine power, driveline performance, and thermal metrics in real time.

Displays long-distance CAN communication status and key operational data.

Customizable UI tailored for bulk material transport applications.

🚛 Garbage Compactor Trucks

Display compaction pressure, tailgate status, and rear-view camera feed.

Visual alerts for hydraulic faults and overload conditions.

Ensures operators maintain full situational awareness during frequent start-stop operations.

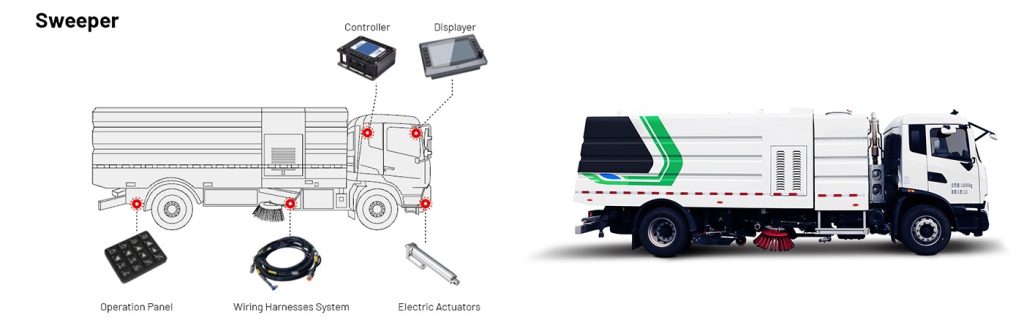

🧹 Street Sweepers

Real-time visualization of brush speed, fan operation, and water spray levels.

Enables intuitive control through a touchscreen interface.

Adapts display layout dynamically based on operating modes or road feedback.

🛻 Sprinkler Trucks

Monitor spray coverage, tank levels, and pump speed in real time.

Display directional nozzle angles for precise control.

Supports outdoor readability and operation under high-vibration conditions.

♻️ Recycling Collection Vehicles

Show lifting arm position, compartment status, and sorting indicators.

Alerts for bin overload, misalignment, or malfunction.

Interfaces with CAN-based subsystems to coordinate sorting and loading.

🚜 Tractors

Real-time display of engine status, hydraulic performance, and implement activity.

Provides fault alerts and operational feedback to enhance control and precision farming.

Supports multi-protocol communication for seamless system integration.

🌾 Combine Harvesters

Visualizes the status and progress of cutting, threshing, and collection systems.

Synchronizes sensor and mechanical subsystems for efficient and stable harvesting.

Customizable interface adapts to various crops and operating conditions.

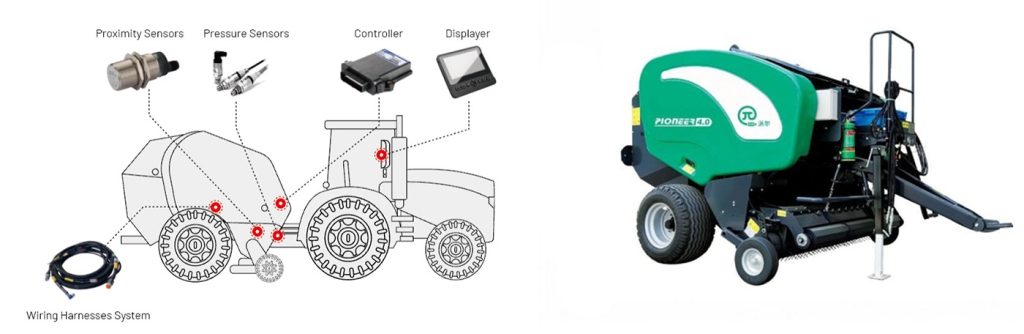

🔄 Round Balers

Displays key parameters and progress for baling, wrapping, and ejection.

Real-time feedback ensures consistent bale density and accurate timing.

Touchscreen interface with alerts reduces manual intervention.

💧 Crop Sprayers

Monitors boom arm position, nozzle pressure, and spray cycle timing.

Displays spray progress and warning indicators for operational precision.

Enables efficient application without GPS dependency.