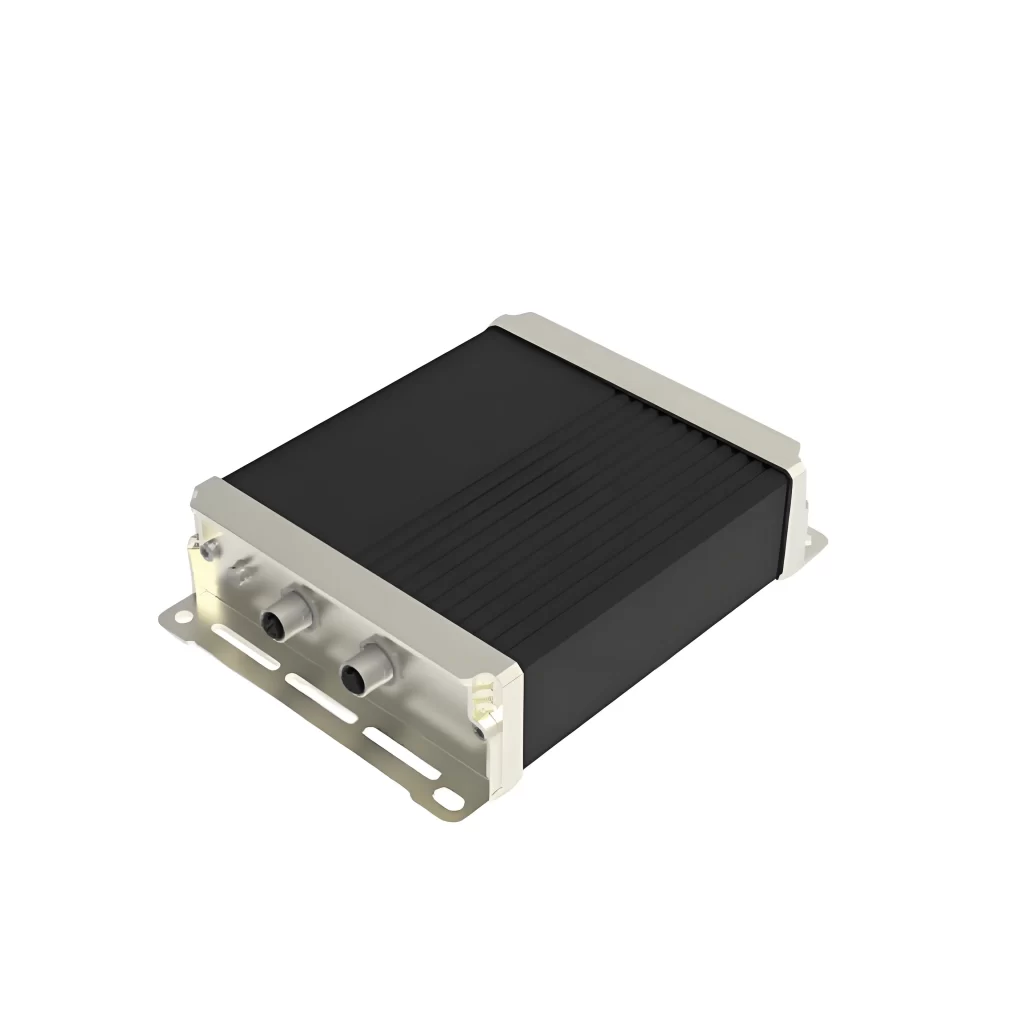

Programmable Controller for Mobile Machines with CAN Bus & IP67

SonnePower’s programmable controller for mobile machines combines CAN Bus communication, IP67 protection, and flexible I/O design to deliver stable performance in harsh environments.

Engineered for off-road vehicles such as construction, sanitation, and agricultural machinery, it supports CoDeSys programming and ensures long-term reliability under shock, vibration, water, and dust.

Select Mobile Machine Controller

| SPC-SFMC-X3632A | SPC-SFMC-X0402A | SPC-SFMC-X2214A | SPC-SFMC-X2424A | SPC-SFMC-X2024G | SPC-SFMC-X2424C | SPL0601 | |

|---|---|---|---|---|---|---|---|

| Power Supply | 8~32VDC | 8~32VDC | 8~32VDC | 8~32VDC | 8~32VDC | 8~32VDC | 8~32VDC |

| Total I/O | 66 (36 Inputs/32 Outputs) | 4 (4 Inputs/2 Outputs) | 29 (22 Inputs/14 Outputs) | 44 (24 Inputs/24 Outputs) | 44 (24 Inputs/24 Outputs) | 44 (24 Inputs/24 Outputs) | 66 (38 Inputs/30 Outputs) |

| IP Rating | IP 67 | IP 67 | IP 67 | IP 67 | IP 67 | IP 67 | IP 67 |

| Operating temperature | -40~85℃ | -40~85℃ | -40~85℃ | -40~85℃ | -40~85℃ | -40~85℃ | -40~85℃ |

| Ethernet interface | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| CAN interface | 3 | 3 | 2 | 2 | 2 | 2 | 3 |

| RS 232 interface | 1 | 1 | 1 | 1 | 1 | 1 | 4 |

| RS 485 interface | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| Programming Environment | CoDeSys3.5 | CoDeSys3.5 | CoDeSys3.5 | CoDeSys3.5 | CoDeSys3.5 | CoDeSys3.5 | CoDeSys3.5 |

| Get Quote | Get Quote | Get Quote | Get Quote | Get Quote | Get Quote | Get Quote |

Browse Sonnepower CAN Bus Controllers

Applications of Rugged Controller in Mobile Machinery

SonnePower controllers deliver stable and reliable control solutions for construction equipment, enabling precise management of hydraulics, motors, and sensors.

With IP67 protection, they withstand dusty and high-vibration environments and support flexible programming via CoDeSys to meet complex automation needs.

1. Aerial Work Vehicle 🏗️

Controls hydraulic cylinders for smooth lifting/lowering.

Monitors tilt sensors & safety switches.

Supports CAN bus for remote diagnostics.

2. Drilling Rig ⛏️

Regulates drill speed & pressure hydraulics.

Real-time sensor data for efficient drilling.

Flexible CoDeSys programming.

3. Excavator 🚜

Controls boom, arm, and bucket hydraulics.

Load sensing & safety monitoring.

Multi-channel I/O & CAN communication.

4. Loader 🚛

Manages bucket lift & tilt hydraulics.

Monitors speed & oil pressure.

Automates loading sequences.

5. Crane 🏗️

Controls boom extension, rotation & movement.

Prevents overload via load sensors.

Supports remote control & data logging.

SonnePower controllers are widely applied in mining and heavy-duty transport vehicles, where harsh environments and mission-critical reliability are daily challenges. With high ingress protection, wide operating temperature range, and full CAN bus protocol support (including CANopen, J1939, and custom protocols).

Our controllers enable precise control of complex systems such as powertrains, hydraulics, braking, and telematics. Engineered for durability and flexibility, they are trusted across a variety of vehicle platforms.

🛻 Mining Trucks

Enable precise control of propulsion, braking, suspension, and dump bed systems. Support real-time diagnostics and remote monitoring.

🚛 Articulated Dump Trucks

Control steering and articulated frame functions under rough terrain. Optimized for off-road stability and performance.

⛏️ Underground Loaders

Designed for confined, low-visibility environments. Features safety redundancy, robust I/O performance, and fault-tolerant logic.

🚚 Heavy Haul Trucks

Handle high-power drivetrains and long-distance CAN communication. Ideal for bulk material transport in open-pit mining operations.

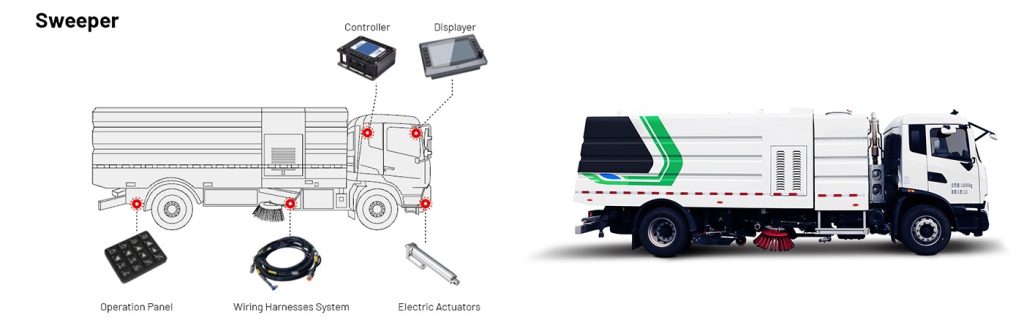

SonnePower controllers are tailored for the demanding control needs of sanitation vehicles, where safety, automation, and system coordination are essential. With support for distributed I/O, multiple CAN bus interfaces, and IP67-rated protection, our controllers provide precise control of sweeping, lifting, compacting, and water spray systems.

🚛 Garbage Compactor Trucks

Control the hydraulic compaction system, tailgate lift, and rear-view safety functions. Ensure stable operation under heavy loads and frequent stops.

🧹 Street Sweepers

Coordinate sweeping brushes, suction fans, and water spray systems. Enable real-time control and adaptive response to road conditions.

🛻 Sprinkler Trucks

Manage spray pressure, water pump speed, and directional nozzles. Suitable for both urban road dust suppression and landscaping.

♻️ Recycling Collection Vehicles

Control automated lifting arms, compartment separation, and load sensors. Support CAN-based communication between subsystems for efficient sorting.

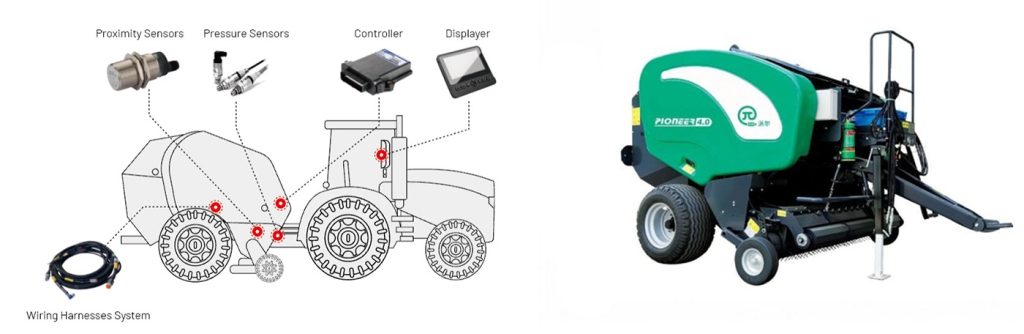

SonnePower controllers empower modern agricultural machinery with intelligent control, automation, and robust performance. Designed for outdoor environments with dust, moisture, and variable loads, our controllers support advanced hydraulic control, CAN BUS communication, and smart data integration.

With flexible I/O and real-time responsiveness, they enhance operational efficiency, reliability, and ease of use in agricultural tasks.

🚜 Tractors

Control engine parameters, hydraulic systems, and auxiliary attachments. Support precision agriculture through reliable logic and responsive performance.

🌾 Combine Harvesters

Manage grain cutting, threshing, and collection systems. Synchronize multiple mechanical and sensor subsystems for efficient and stable harvesting.

🔄 Round Balers

Automate bale formation, wrapping, and ejection processes. Ensure accurate timing and consistent compression with real-time control feedback.

💧 Crop Sprayers

Control boom arms, nozzle pressure, and spray timing. Achieve accurate application and efficient resource usage without relying on GPS systems.