Product Description

The SPC-SFMC-X2424C IP67 CAN Bus controller is a high-performance unit designed specifically for construction machinery. It offers excellent dustproof, waterproof, and vibration resistance, making it ideal for harsh outdoor working conditions.

Supporting CoDeSys programming and multiple communication interfaces, it easily integrates with various sensors and actuators. This controller helps customers achieve intelligent control and efficient operation of equipment, while reducing maintenance costs and improving overall productivity.

SPC-SFMC-X2424C Controller Advantages

Rugged Durability

With an IP67 protection rating, it is dustproof, waterproof, and corrosion-resistant, specially designed for harsh outdoor environments to ensure long-term stable operation.Extreme Environment Adaptability

Supports a wide voltage and temperature range, maintaining high performance even under high heat, cold, and strong vibration conditions.High Integration and Flexibility

Equipped with abundant input/output interfaces to meet complex control needs, allowing seamless connection with various sensors and devices.Easy Customization and Upgrades

Supports CoDeSys 3.5 programming for fast development and secondary customization, adapting to the personalized requirements of different construction machinery.Reduced Maintenance Costs

Built-in short-circuit, overheating, and miswiring protection effectively reduce failure rates, minimizing downtime and maintenance frequency.

Specification

| Parameter | Value |

|---|---|

| Working Voltage | 8–32 V DC |

| Operation Temperature | -40 to +85℃ |

| Protection Class | IP67 |

| Weight | 1.0 kg |

| Housing Material | Cast aluminum shielded housing |

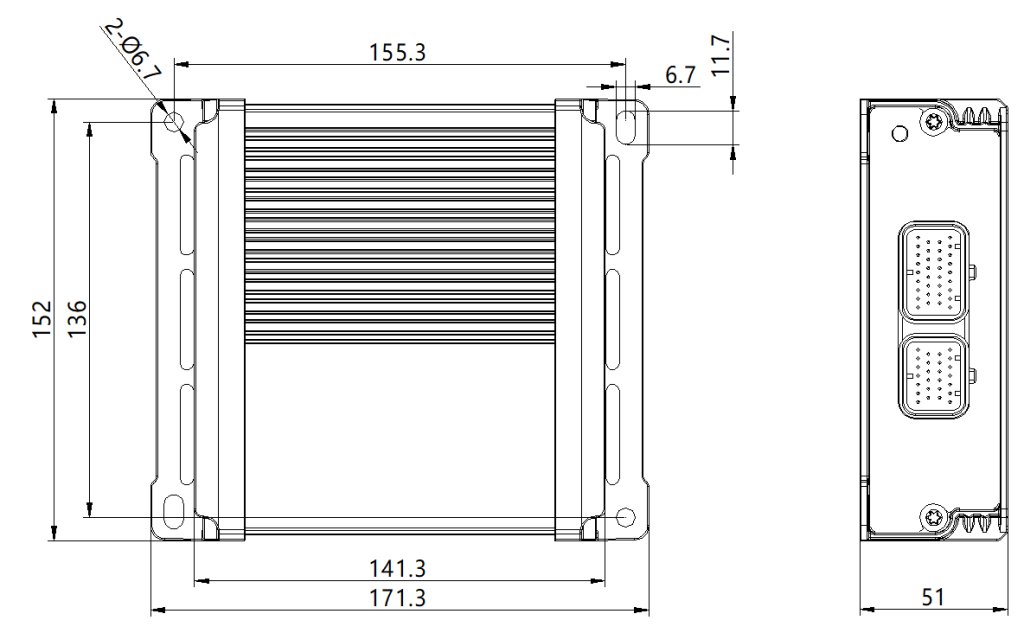

| Dimensions (L×W×H) | 171.3 × 155.3 × 51 mm |

| Assembly | 4 pcs M5 × 30 mm Screws |

| Connections | 60-Pin AMP Connector |

| Programming System | CoDeSys 3.5 |

| Communication Interfaces | 2 × CAN, 1 × RS232 |

| Total I/O | 44 channels (24 inputs / 24 outputs) |

| Input Configuration | Up to 24 configurable inputs |

| Digital Inputs | 24 × DIH/L |

| Analog Inputs | 16 × AIU, 6 × AII, 2 × AIR |

| Pulse Inputs | 6 × PI, 2 × PI(AB) |

| Digital Outputs | 24 × DOH |

| PWM Outputs | 20 × PWMH |

| Voltage Output | 1 × Vout (+5V / +10V, Max 250 mA) |

| Analog Output | 1 × AO (0.6–5V, Max 250 mA) |

Dimensions

Application

-

Excavators

For controlling hydraulic arms, swing mechanisms, and bucket operations with real-time responsiveness and system diagnostics. -

Bulldozers

Manage engine performance, blade position, and traction control under heavy-duty workloads and vibration-intensive environments. -

Cranes and Aerial Lifts

Ensure safe and coordinated movement of lifting arms, hoists, and safety interlocks, supporting remote monitoring via CAN bus. -

Road Rollers and Compactors

Monitor and control vibration levels, engine operation, and compaction feedback for consistent performance on site. -

Pavers and Asphalt Machines

Regulate screed controls, temperature zones, and conveyor systems for high-precision surface laying. -

Drilling Rigs

Control drilling rotation, feed pressure, and motor synchronization in tough, dusty, and high-vibration conditions. -

Skid Steer Loaders and Wheel Loaders

Manage steering systems, hydraulic attachments, and operator interface with customized I/O logic.